Sending files for new Cad-Cam laser melting service

-1.png)

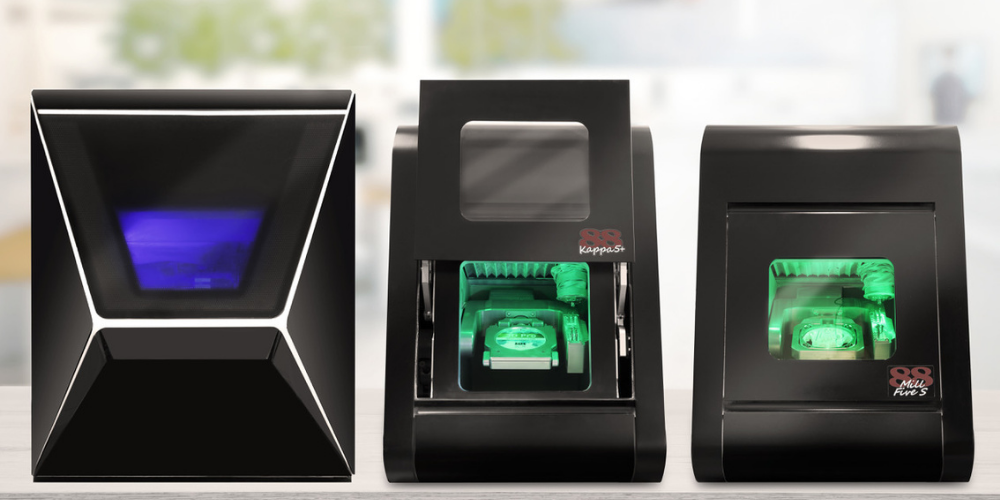

Thanks to decades of experience in dental alloy research and production, we are pleased to announce to the market that our digital production centre 88dent has increased its production capacity with the introduction of a new technology: Laser melting HD3

-High Definition

-High Density

-High Details

The 88dent centre, exploiting its know-how in the production of semi-finished zirconia products, has implemented a new type of processing.

This type of processing is achieved thanks to certified raw materials, for dental use, of the highest level and the Print genius 150 printer produced by the Italian multinational Prima additive.

This produces a semi-finished product with optimum characteristics for finishing and finalisation by the dental technician:

Chemical composition % : Co 64.40 Cr 28.00 Mo 5.50 Si 0.70 Mn 0.60 C <0.30 Other elements 0.50

Vickers hardness HV10 : 290 HV

Density: 8.4 g/cm3

Melting range

T-solids: 1200

T-liquids: 1380

CDT coeff. thermal expansion: 14.2x10-6

Thanks to these characteristics, the obtained artefacts are perfectly compatible with most dental ceramics on the market.

The metal-ceramic bond is guaranteed thanks to reduced oxidation during heat treatments. Stability during firing is guaranteed by a homogenisation treatment carried out in a controlled atmosphere by 88dent on the manufactured article before shipment.

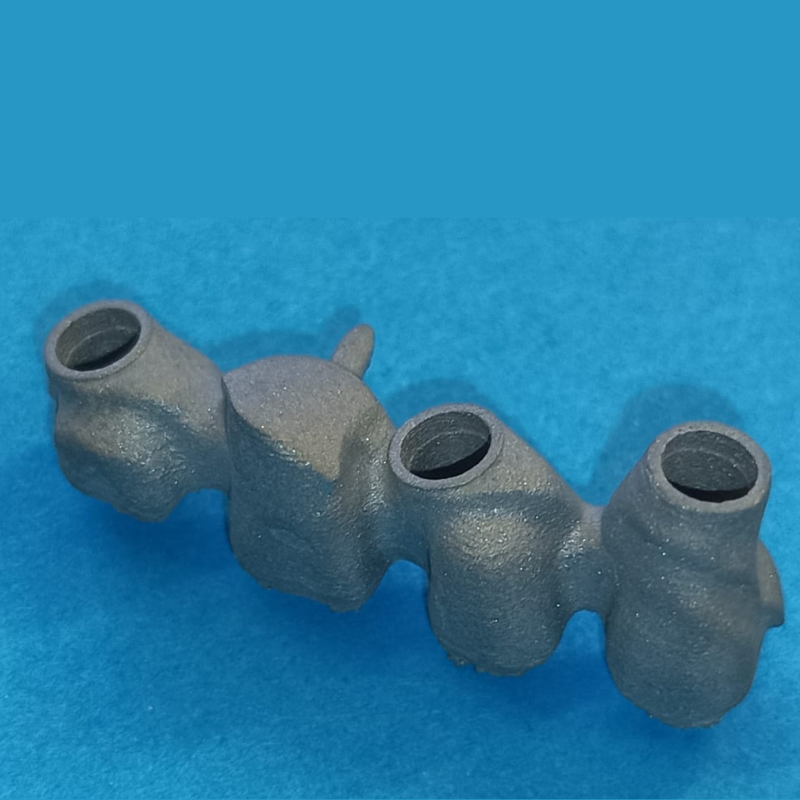

Chromocobalt element in hd3 laser melting technique on natural elements

Co-Cr screwed element in hd3 laser melting technique to be ceramicised or with pin for commercial teeth.

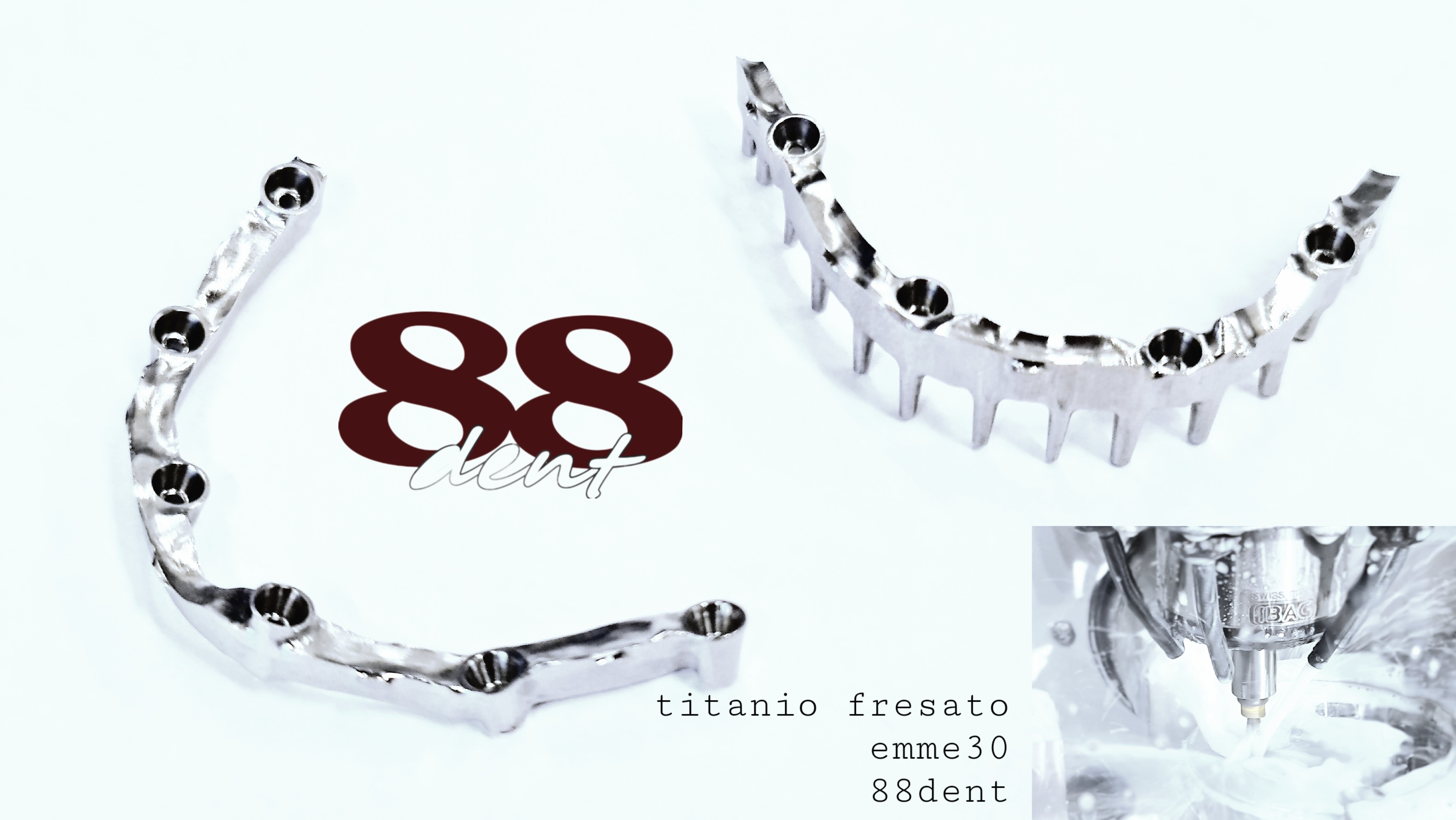

Chromocobalt primary bar in h3d laser melting technique

Discover some of our work:

.png)

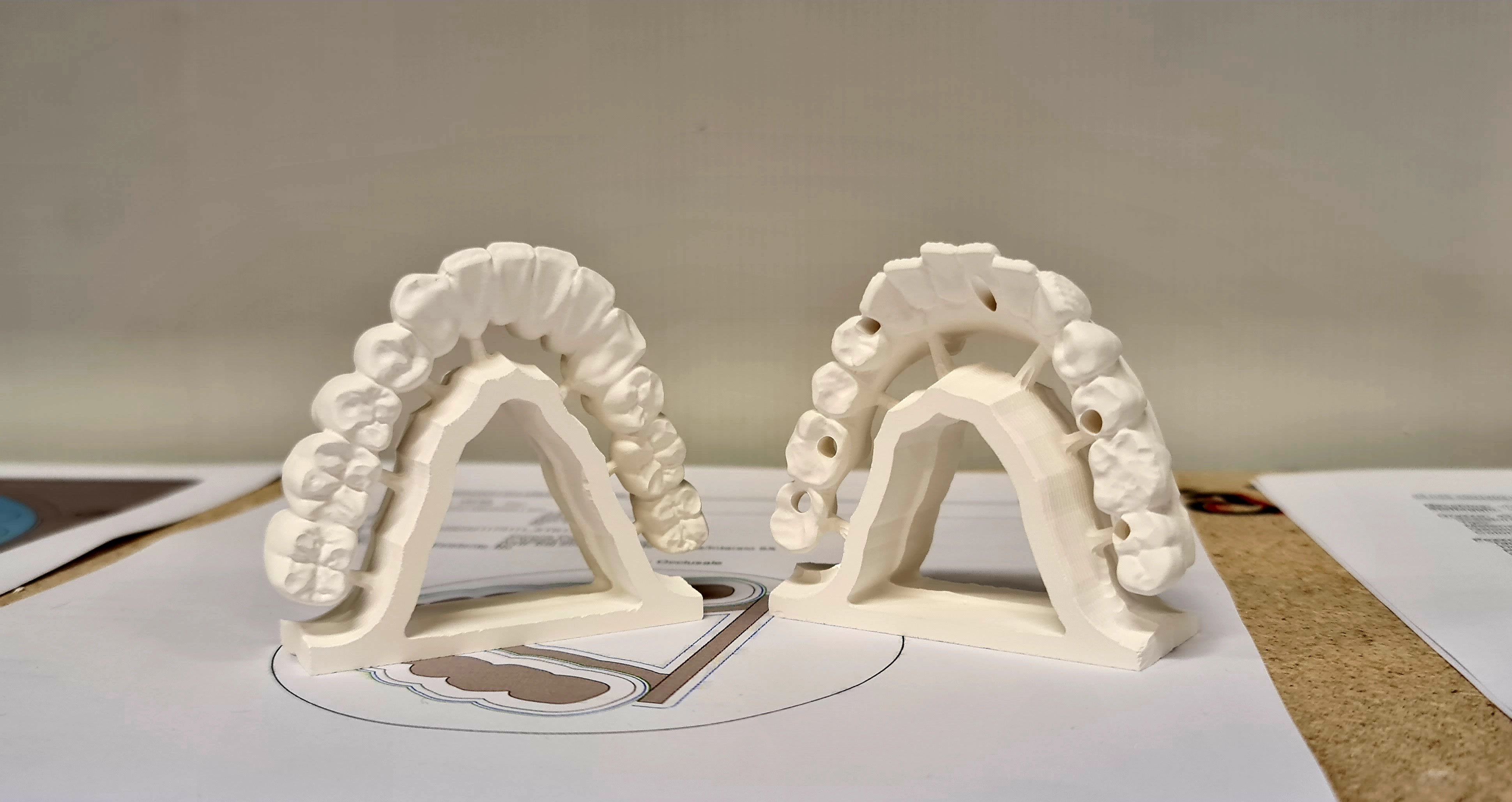

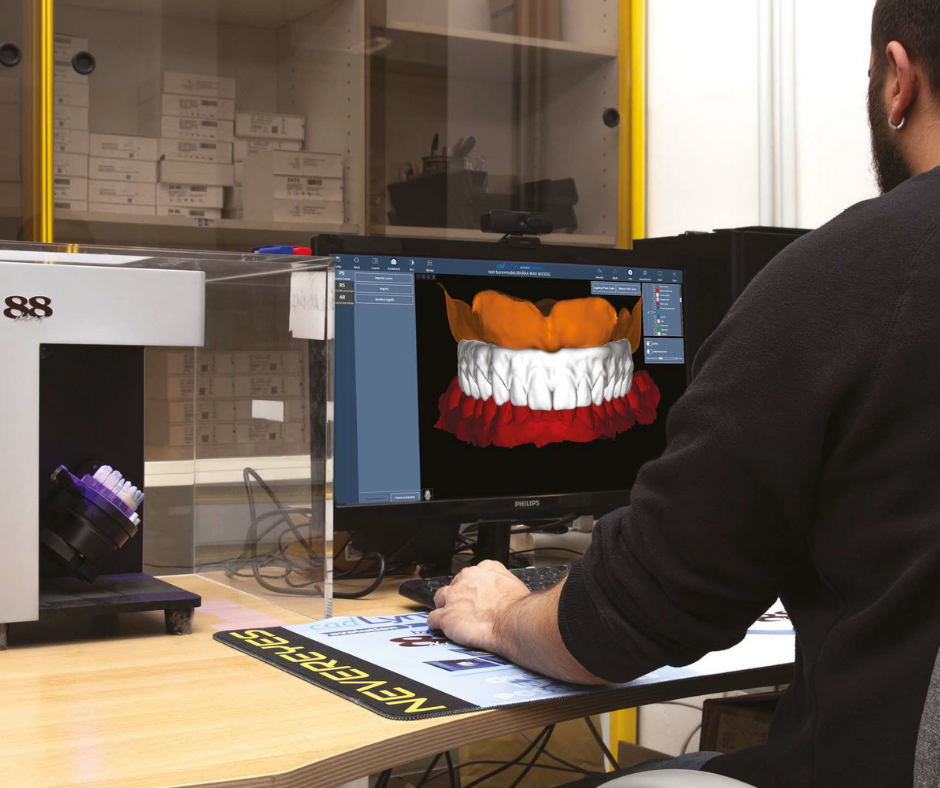

Our digital production centre, with the experience of our experts, offers processing with the new 3DPro zirconia 88dent

3D Pro zirconia is a complete revolution in the production of crowns, bridges and large monolithic restorations.

Its aesthetic performance far exceeds expectations, enabling the dental technician to finalise his work with confidence using simple and effective protocols, without having to resort to complex infiltration and surface characterisation techniques.

3D Pro, a revolutionary Multicolour layered zirconia with decreasing chroma saturation, is characterised by an excellent aesthetic gradient.

This produces a semi-finished product with optimum characteristics for finishing and finalisation by the dental technician:

Aesthetics: Translucency 57%

Sintering density: >6.0g/cm3

Flexural strength: Cervical part 1050MPa

Breaking strength: 5MPam0.5

Hardness: (Hv10)1250

.jpg)

.jpg)

Zirconia

.jpg)

.png)

Our digital production centre offers milled Titanium (Grade 5) machining using our state-of-the-art specialised milling machines.

Titanium is a metal that in its pure state has some remarkable properties:

It is the ninth element in order of industrial use and the fourth among metals in terms of abundance, preceded only by aluminium, iron and magnesium. Nevertheless, its extraction, which is rather complex and costly, has only been possible since the first half of the 1900s by metallurgist W.J. Kroll. The difficulties in extracting it essentially stem from its high affinity for elements that are widespread in the air - such as hydrogen, oxygen and nitrogen - resulting in very stable solid solutions characterised by high hardness and brittleness. At room temperature, titanium has a compact hexagonal structure (hcp) called a, which transforms into a body-centred cubic (ccc) b-phase above a temperature of 882.5°C. When pulverised, it burns in air and exposed surfaces become passivated, can be polished to a mirror-like shine, and does not react with alkalis and most existing acids: because of these properties, it is present in many alloys.

As with other metals, alloys are being studied for titanium to improve the material's mechanical and physical properties.

Characteristics of Titanium and its Alloys

Biocompatibility

Corrosion resistance

Radio-transparency

Absence of flavour

Thermal conductivity

Lightness

Chemical composition % : Carbon≤ 0.08 , Nitrogen ≤ 0.03 Hydrogen ≤ 0.015 Iron≤ 0.20 Oxygen≤ 0.18 Aluminium 5.5~6.5 Vanadium 3.5~4.5 Titanium Remainder

Mechanical properties:

Breaking load: 895 MPa (min)

.jpg)

.jpg)

Titanium

.png?width=9233&height=4830&name=88dent_logo@4x%20(2).png)

.png)