How does the intraoral scanner work? 10issues you haven't asked yourself

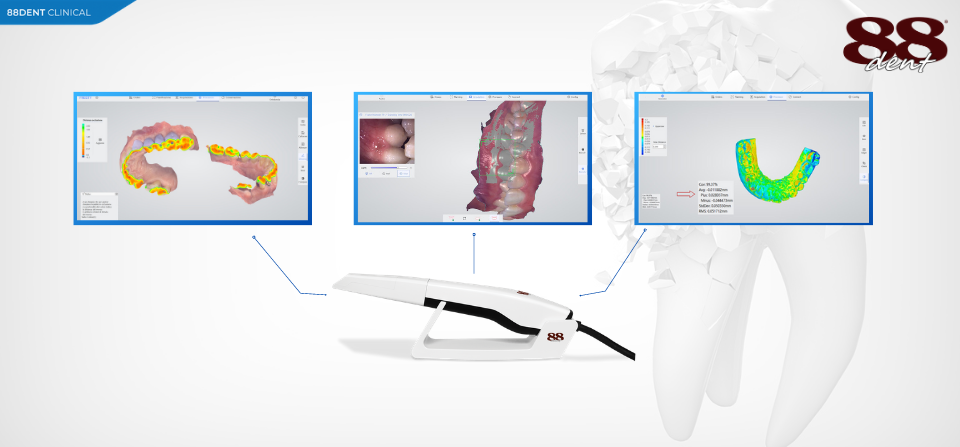

The intraoral scanner is a special 3D scanner capable of taking dental impressions in digital format. This is done by acquiring a series of images, subsequently processed by the software, which reproduce all the elements of the oral cavity, maintaining consistency with the real characteristics of the same and reducing the margin of error to a minimum.

In this article, based on 10 questions, we will explain what an intraoral scanner is, how this technologically advanced tool works and how to choose the best intraoral scanner.

The main questions about the intraoral scanner

1. What is the intraoral scanner?

As mentioned in the previous section, the intra-oral scanner is a 3D scanner used in Dentistry, which allows the three-dimensional measurement of what is inside the oral cavity. From the shape to the dimensions of the dental arches, up to the position of the single elements, can be detected by the simple emission of the light beam. The information collected is then processed by special software that accurately reconstructs a three-dimensional model that can be viewed on the monitor.

From the video view you can then rotate the created model and analyse the characteristics of each angle of the oral cavity.

2. How does the intraoral scanner work?

The intra-oral scanner, through a beam of light (structured light or laser) projected onto the surface of the teeth, is able to capture, by means of high-resolution cameras, dental arches, implants and their dimensions, and captures the distortion that this beam undergoes when it hits these structures. This is possible because, when the beam emitted by the instrument hits the various structures inside the oral cavity, it undergoes a distortion that is recorded by the cameras and, through special software, highlighted within the 3D model.

First, a sort of tracing of points will be created from which a triangulation between these points, or mesh, will be generated to create a physical representation of the scanned material. The final 3D model that will be formed will represent the virtual structure of the patient's oral cavity in both shape and size.

3. Digital impression and traditional impression: what is the difference?

The traditional impression involves the use of a metal plate (or impression tray) that is filled with paste and placed inside the patient's mouth for a few minutes. For the patient, the discomfort was considerable, including any gag reflex caused by the plate itself and anxiety. In addition, the risk of damaging the impression is not insignificant, which would lead to the patient having to undergo another impression.

With the intraoral scanner, on the other hand, simply passing the scanner inside the patient's mouth for a few seconds, with the possibility of momentary suspension of the impression, is enough to obtain a digital impression in real time. This also translates into greater efficiency, speed and less discomfort for the patient.

4. Is the intraoral scanner fast?

Of course, the intraoral scanner immediately releases the 3D model of the oral cavity analysed using special software. In this model, the structure of the arches and the dental elements will be perfectly reconstructed thanks to the creation of a model that is absolutely faithful to reality.

5. Is the intraoral scanner invasive?

The intraoral scanner is completely non-invasive. The handpiece with high-resolution cameras is inserted into the patient's mouth and scanned for a few minutes, with the possibility of pausing the operation if necessary. The images taken are then transferred directly to the monitor.

It is therefore easy to understand how this operation does not cause the slightest harm to the patient, compared to the use of the traditional impression, which is extremely annoying and does not allow any kind of interruption during the fabrication phase.

6. What are the possible clinical applications of the intraoral scanner?

The intraoral scanner can be used to create 3D models for use in orthodontics, for the development of implants, but also for a more complete and detailed view of teeth and gums.

Basically, this tool can be an excellent ally for all interventions involving the conformation of the arches themselves, as it allows you to create an extremely precise and realistic 3D model.

The intraoral scanner can be used as an archive of the patient's mouth as, whatever happens, it will be possible to replicate the same anatomical shapes of the patient's teeth.

7. What features should an intraoral scanner have to meet the needs of the practitioner?

An intraoral scanner should have mathematical accuracy of the models derived from the scan, maximum resolution and precision. It should also be fast and practical to use, with the possibility of acquiring colour images.

8. What are the patient benefits of using the intraoral scanner?

Undoubtedly, the main advantage for the patient is the absence of discomfort associated with the use of this instrument for obtaining dental impressions. Not to be underestimated is the saving in terms of sessions, but also the possibility of involving the patient in the different operations, as on the monitor the patient can clearly see the details of his mouth and understand which interventions will be carried out on it.

9. What are the advantages for the professional of using the intraoral scanner?

The professional who chooses to use the intraoral scanner will be able to take advantage of the speed of this instrumentation, which will allow immediate evaluation of the impression, intervening where there are any imperfections without completely repeating the work, which would be the case with the traditional technique. This immediacy will then allow the production of the artefact by simply sending the file, reducing the technical times of the past when the impression had to be delivered manually.

Finally, the reduced weight and extreme manageability of the instrumentation will make the work easier in all its phases.

10. What kind of maintenance does an intraoral scanner need?

As with any instrumentation, sterilisation of the equipment is necessary. This can be done by rinsing the probe head under water and drying it with absorbent gauze and alcohol. The probe should then be disassembled, covered with gauze and placed inside the sterilisation bags and disinfected by steam at 134°C for 6 minutes, or at 121°C for 15 minutes.

For the rest, the instrumentation does not require any particular maintenance, except for its calibration once a week, which takes just a few minutes.